Fiberglass grating solutions are a flexible option for a variety of industrial, industrial, and in many cases non commercial software. Made from established fiberglass resources, these gratings offer an array of advantages, leading them to be a common option across distinct businesses. Here’s all you need to know about fiberglass grating methods:

1. Durability: FRP grate techniques are known for their outstanding sturdiness. They are resistant to rust, oxidation, and chemicals, making them ideal for tough situations including chemical plant life, marine establishments, and wastewater therapy plant life. In contrast to metal gratings, fiberglass gratings usually do not corrode or degrade after a while, ensuring long term stability and cost-performance.

2. Light: One of several crucial great things about fiberglass grating systems could be the light in weight character. Compared to standard components like metallic, fiberglass gratings are significantly lighter in weight, which makes them quicker to take care of, transfer, and mount. This attribute also lessens the structural fill on complexes and websites, resulting in decrease building and servicing expenses.

3. Power: Regardless of becoming light, fiberglass grating solutions offer you remarkable strength and weight-displaying functionality. They may withstand hefty loads and high-visitors areas without limiting safety or efficiency. This durability-to-body weight rate helps make fiberglass gratings appropriate for a variety of applications, which includes flooring surfaces, pathways, ramps, and systems.

4. Safety: Fiberglass grating solutions were created with basic safety in your mind. They have slide-proof surface areas which provide traction in moist or greasy circumstances, lowering the danger of slips, trips, and drops. Furthermore, fiberglass gratings are non-conductive and non-magnet, causing them to be appropriate for use within electric powered and magnetic-sensitive conditions.

5. Straightforward Upkeep: Maintenance needs for fiberglass grating techniques are minimum. They generally do not call for painting, finish, or galvanizing to keep their look and satisfaction. Routine cleaning with soap and water is usually ample to hold fiberglass gratings in top condition, conserving money and time on maintenance charges.

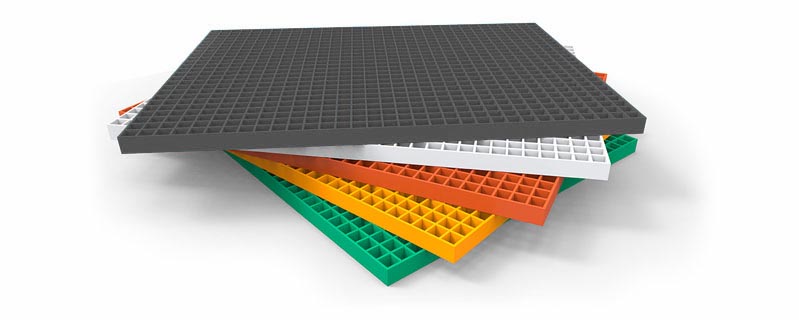

6. Changes: Fiberglass grating systems are available in a variety of measurements, hues, and layouts to suit particular project specifications. They are often easily minimize, shaped, and constructed on-web site to suit unique measurements and templates. This flexibility permits creative design and style solutions and easy incorporation into existing buildings.

To conclude, fiberglass grating methods provide a mixture of longevity, light-weight, strength, safety, effortless maintenance, and changes possibilities, making them a preferred option for an array of industrial and professional apps.